Finally, I have the boat moved. I've ordered some clamps and a few other things and now I'm just waiting on some electric wiring to be completed in the garage and I'll be underway.

Back in CT the boat was looking particularly derelict. Here is a photo of the sorry state I found her in.

Here's another of the Hitia loaded on to the back of a dump truck. $30 toll fee going over the GW bridge!

Once the wiring is complete and I can see, I've got a bit of sweeping and a lot of organizing to do then I'll be back at work on the boat once again. Thanks to Jim Osowicki for his help with loading and the use of his truck!

Wednesday, December 12, 2012

Monday, December 3, 2012

A Quick Update...

So I have secured some garage space over in Hackensack, NJ close to where I work. The space is about 19' x 12' so it should accommodate the boat, tools and whatever else I'll need. It might get a little tight once I'm all set up, but if I can work in Kevin's basement, then this should be a breeze!

Kevin and I got together over Thanksgiving weekend to talk about the future of the boat. He has agreed to take on the remainder of the mast work, tiller arms, and maybe some of the cleats and other small stuff. I'm hoping to have the boat moved in by this weekend, but if I can't borrow a truck, at the very least I'll have the beams and epoxy and whatever else I can stuff into the back of my Jetta.

Photos and more to come!

Kevin and I got together over Thanksgiving weekend to talk about the future of the boat. He has agreed to take on the remainder of the mast work, tiller arms, and maybe some of the cleats and other small stuff. I'm hoping to have the boat moved in by this weekend, but if I can't borrow a truck, at the very least I'll have the beams and epoxy and whatever else I can stuff into the back of my Jetta.

Photos and more to come!

Monday, November 26, 2012

Floor Installation

Following the move, Kevin and I both realized the incredible determent of having the boat stored halfway between Boston and New York City. With that in mind, and having the overwhelming itch to keep going and finish that which we have started, I began looking into storing the boat locally, in New Jersey, where I'll be able to get to it during the week and make more progress.

Without the use of Kevin's tools and space, and awesome clamps, I'll be moving forward with a limited set of tools and equipment (and experience). I'll be making most of the posts from here on out. Just gonna take small nibbles out of the project and watch it evolve, one step at a time.

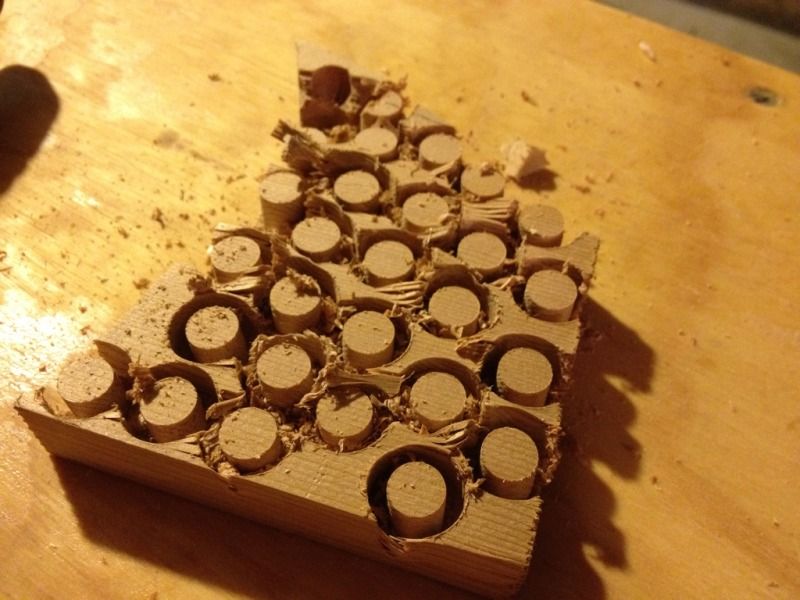

Here is a picture of the partially completed floor installation:

The jugs and varnish are there to add weight and help seal down the floor. I used a compass to trace the holes and cut out the circles using a jig saw. This will be finished up with a layer of fiberglass for added strength.

The other hull still needs its final side of glass, below deck painting and floor installation. After that I'll be finishing the up the beams and sealing the hulls.

Wish me luck!

Wednesday, August 8, 2012

Fiber glassing the hulls

Now that the hulls are assembled they won't fit back into the basement any more. It's been ok to keep them outside so far but the sunshine won't last forever so we are moving up the fiber glassing job to protect them while they are out in the weather.

The paint job looks a bit messy up on the saw horses but all those areas won't show.

All the stitches are out and the keel has been rounded over so we can put a piece of glass tape along the keel joint. This area is going to get the most abuse pulling the boat up on beaches so it gets a triple layering of fiberglass. The first layer is this tape and then the two side pieces will overlap over keel as well. We also put a bead of epoxy down to build up the radius and add more protection to the wooden keel strip.

Next we unrolled the 4oz fiberglass over the size of the hull and tacked it in place some epoxy where we couldn't hold it with tape.

Then we finally got down to spreading on the epoxy. We had been dreading the fiber glassing job and what would happen if we messed it up but it really wasn't that bad.

The fiberglass cloth does want to wrinkle as it laps over the curved edge of the keel but we kept at it and got all the wrinkles spread out.

The fiberglass also wraps up onto the skeg and smooths out the transition. This area is probably going to require some filler and sanding later but is looking pretty good.

We also had to notch the cloth around the lash pad supports. We ended up just glassing down to the edge and trimming with a razor blade which made a pretty clean edge.

Then we just had to keep moving back between the two hull as each fiberglass job cured.

The paint job looks a bit messy up on the saw horses but all those areas won't show.

All the stitches are out and the keel has been rounded over so we can put a piece of glass tape along the keel joint. This area is going to get the most abuse pulling the boat up on beaches so it gets a triple layering of fiberglass. The first layer is this tape and then the two side pieces will overlap over keel as well. We also put a bead of epoxy down to build up the radius and add more protection to the wooden keel strip.

Next we unrolled the 4oz fiberglass over the size of the hull and tacked it in place some epoxy where we couldn't hold it with tape.

Then we finally got down to spreading on the epoxy. We had been dreading the fiber glassing job and what would happen if we messed it up but it really wasn't that bad.

The fiberglass cloth does want to wrinkle as it laps over the curved edge of the keel but we kept at it and got all the wrinkles spread out.

The fiberglass also wraps up onto the skeg and smooths out the transition. This area is probably going to require some filler and sanding later but is looking pretty good.

We also had to notch the cloth around the lash pad supports. We ended up just glassing down to the edge and trimming with a razor blade which made a pretty clean edge.

Then we just had to keep moving back between the two hull as each fiberglass job cured.

Sunday, July 29, 2012

Stem adjustments

The goal of every project is to learn from your mistakes - and so it is with this canoe build. It's time to laminate the aft stem and see if I'm any better at estimating the spring-back to get the right stem profile. By the time I get to the second canoe maybe I'll have the hang of it down.

So on we go to gluing up the aft stem. I used more clamping points to better capture the curvature of the stem and also made sure to maintain the curvature through past the eventual end points. I still wish I had more clamps but it turned out fine and there were not gaps in the glue joints.

So what were the results you ask? Better, but not perfect. In the last installment the fore stem came out alright structurally but I overestimated the spring-back and that made the curve a bit too sharp. The aft stem is close, but the after moving it around to find the position that matches the drawn profile the best the area that connects to the keel is too short and will need to be lengthened. Mr. Oughtred draws such a beautiful boat it would be a shame to change the stem profile even slightly because of lamination errors so I'll be planing these stems down until they match the plans as perfectly as possible.

First up is the fore stem (the bottom one) and you can just barely see that at point of greatest deviation from the plans I had to take off almost a whole lamination layer thickness. This was then added back on the back side using a strip that was tapered on its ends to roughly match the amount removed. The result is a front face that matches the plans and fairly constant thickness. Almost like I did it right the first time!

Next it's time to adjust the aft stem. This one started much closer and only took a bit of cleaning up, but then it came time to beef up the too-short connection with the keel. It worked out that I could take the section that was cut off to from the bottom keel mating surface and glue it back on the top side of the stem. It looks a bit clunkier than the fore stem's keel connection but the aft end could use a bit of extra support since this joint carries the stresses from the rudder. I'll probably still taper it a bit more just so It's prettier to look at as every little detail counts in a small open boat like a canoe.

Well that's as far as I can get using the scraps that are laying around the shop so I'll have to actually invest in some materials soon to start building the strong-back and station molds that form the building jig.

So on we go to gluing up the aft stem. I used more clamping points to better capture the curvature of the stem and also made sure to maintain the curvature through past the eventual end points. I still wish I had more clamps but it turned out fine and there were not gaps in the glue joints.

So what were the results you ask? Better, but not perfect. In the last installment the fore stem came out alright structurally but I overestimated the spring-back and that made the curve a bit too sharp. The aft stem is close, but the after moving it around to find the position that matches the drawn profile the best the area that connects to the keel is too short and will need to be lengthened. Mr. Oughtred draws such a beautiful boat it would be a shame to change the stem profile even slightly because of lamination errors so I'll be planing these stems down until they match the plans as perfectly as possible.

First up is the fore stem (the bottom one) and you can just barely see that at point of greatest deviation from the plans I had to take off almost a whole lamination layer thickness. This was then added back on the back side using a strip that was tapered on its ends to roughly match the amount removed. The result is a front face that matches the plans and fairly constant thickness. Almost like I did it right the first time!

Next it's time to adjust the aft stem. This one started much closer and only took a bit of cleaning up, but then it came time to beef up the too-short connection with the keel. It worked out that I could take the section that was cut off to from the bottom keel mating surface and glue it back on the top side of the stem. It looks a bit clunkier than the fore stem's keel connection but the aft end could use a bit of extra support since this joint carries the stresses from the rudder. I'll probably still taper it a bit more just so It's prettier to look at as every little detail counts in a small open boat like a canoe.

Well that's as far as I can get using the scraps that are laying around the shop so I'll have to actually invest in some materials soon to start building the strong-back and station molds that form the building jig.

Saturday, July 14, 2012

Let's get laminating

I decided to start with the MacGregor partly because it is the more versatile of the two canoes, but mostly because I already had 1" strips of Douglas fir lying around which is the right width for the MacGregor stems.

I marked the inboard edge of the stem on an old desk top by laying out the plans and using a sharp screw point every few inches. You can then take a pencil and darken each hole to make them easier to see. The strips on hand were a bit thicker than in the plans so I tried to leave a bit more allowance for spring back. I'm not sure how it's going to turn out but i'm hoping its close enough to be usable.

Each lamination is just under 1/4" thick which makes the four layers together about 7/8" thick, a bit short of the 1" target. I was thinking the epoxy in the joints would add some of that width back but they were pretty tight. I may be adding some more material to get the shape right once the stem is off the forms anyway, otherwise I'll consider it a bit of weight savings. The un-epoxied strip on the outside is to help keep the tension even along the outside strip, this seemed to help them make the bend easier.

The next day the clamps come off and there is less spring back than I was expecting. That means I'm going to have to plane of some of the thickness in the middle section to get the shape just right and probably laminate another strip on to make it strong enough.

Here is the spring back near the keel - about 3/16".

Here is the spring back near the stem- about 1/4".

All in all a success, but I'm going to try and guess the spring back better for the aft stem and see what this one looks like once its planed down to match the plans exactly. The other thing I'm going to do differently is round the edges of the 2x4 pieces so that the corners aren't pressed into the inside face of the stem.

I marked the inboard edge of the stem on an old desk top by laying out the plans and using a sharp screw point every few inches. You can then take a pencil and darken each hole to make them easier to see. The strips on hand were a bit thicker than in the plans so I tried to leave a bit more allowance for spring back. I'm not sure how it's going to turn out but i'm hoping its close enough to be usable.

Each lamination is just under 1/4" thick which makes the four layers together about 7/8" thick, a bit short of the 1" target. I was thinking the epoxy in the joints would add some of that width back but they were pretty tight. I may be adding some more material to get the shape right once the stem is off the forms anyway, otherwise I'll consider it a bit of weight savings. The un-epoxied strip on the outside is to help keep the tension even along the outside strip, this seemed to help them make the bend easier.

The next day the clamps come off and there is less spring back than I was expecting. That means I'm going to have to plane of some of the thickness in the middle section to get the shape just right and probably laminate another strip on to make it strong enough.

Here is the spring back near the keel - about 3/16".

Here is the spring back near the stem- about 1/4".

All in all a success, but I'm going to try and guess the spring back better for the aft stem and see what this one looks like once its planed down to match the plans exactly. The other thing I'm going to do differently is round the edges of the 2x4 pieces so that the corners aren't pressed into the inside face of the stem.

Monday, July 9, 2012

Painting and keel fairing

Building a boat involves a lot of firsts, and today was the first time we applied paint to the boat. We're using bright white Easypoxy for just about everything that isn't varnished until we sort out a final color scheme - likely white and grey. The outsides will be rolled and tipped, but for the insides we're just brushing.

The sections under the fore and aft decks is fair game for paint at this point as is the area under the seats. These are going to be too hard to get to once the decks and floors are glued on so we're painting them in advance.

We could have just left it with an epoxy coating but it seems prudent to protect the wood as well as possible in case any water works its way into the bilge. The paint is such a bright white it's hard to look at in the sunlight and kind of hard to photograph too. It should be fine for the topsides but it's giving us second thoughts about using it for the deck.

Once the paint dried a bit we flipped the hull over and started fairing around the keel to prep for fiberglassing. All the gaps around the keel are filled with thickened epoxy as well as fairing around the skeg.

The stem is also faired but we stopped short of where the rigging will attach using a heavy duty u-bolt. We put a smaller fillet at the u-bolt location to make room for the backing plates and will blend it into the rest of the stem fairing later.

The last bit of fairing was to tie the stem into the ends of the sheer stringers. Once the epoxy dries we can sand the corner down to make a nice curve.

We also used the extra bits of epoxy to fill the screw, staple and stitching holes. With a bit of sanding the hull should have a nice smooth surface for the fiberglass to lay over. We left some air bubbles in the keel fiberglassing that needed filling so it would be nice to prevent that on the hulls if we can.

The sections under the fore and aft decks is fair game for paint at this point as is the area under the seats. These are going to be too hard to get to once the decks and floors are glued on so we're painting them in advance.

We could have just left it with an epoxy coating but it seems prudent to protect the wood as well as possible in case any water works its way into the bilge. The paint is such a bright white it's hard to look at in the sunlight and kind of hard to photograph too. It should be fine for the topsides but it's giving us second thoughts about using it for the deck.

Once the paint dried a bit we flipped the hull over and started fairing around the keel to prep for fiberglassing. All the gaps around the keel are filled with thickened epoxy as well as fairing around the skeg.

The stem is also faired but we stopped short of where the rigging will attach using a heavy duty u-bolt. We put a smaller fillet at the u-bolt location to make room for the backing plates and will blend it into the rest of the stem fairing later.

The last bit of fairing was to tie the stem into the ends of the sheer stringers. Once the epoxy dries we can sand the corner down to make a nice curve.

We also used the extra bits of epoxy to fill the screw, staple and stitching holes. With a bit of sanding the hull should have a nice smooth surface for the fiberglass to lay over. We left some air bubbles in the keel fiberglassing that needed filling so it would be nice to prevent that on the hulls if we can.

Monday, July 2, 2012

The Plans Arrive

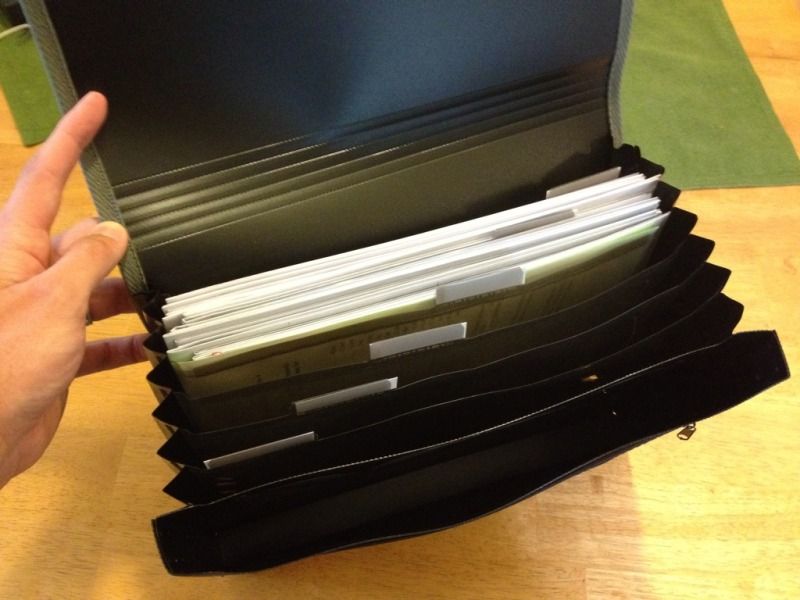

The plans for my two future sailing canoes arrived today from England. Inside the envelope were two smaller envelopes, one with plans for a MacGregor and the other plans for a Wee Rob, both designed by Ian Oughtred.

Opening up the packaging and gently unfolding the pages to get a glimpse of all the wonderful building details is like being a kid on Christmas morning again. These are small but very carefully designed boats and I'm looking forward to the challenge of building something that lives up to the aesthetic potential of the designs.

The Wee Rob plans were all printed on blue print type paper and fit nicely into a new folio I bought to keep this project organized and keep the plans in good condition. The MacGregor plans had one blue print type sheet and the rest were on large photocopy paper. This wasn't a problem of itself, but the paper was a euro dimension and didn't fit when folded. My solution was to refold and then cut off the blank margin to get back to the original drawing paper size.

Now both plans fit nicely in the folio and will have a chance of surviving the rough and tumble life of the boat shop (i.e. my basement). I have a separate section dedicated for keeping track of receipts and that leaves four more sections for future builds!

I'm not in a position to get started on the building just yet, but can't wait to start bringing these beautiful plans to life.

Opening up the packaging and gently unfolding the pages to get a glimpse of all the wonderful building details is like being a kid on Christmas morning again. These are small but very carefully designed boats and I'm looking forward to the challenge of building something that lives up to the aesthetic potential of the designs.

The Wee Rob plans were all printed on blue print type paper and fit nicely into a new folio I bought to keep this project organized and keep the plans in good condition. The MacGregor plans had one blue print type sheet and the rest were on large photocopy paper. This wasn't a problem of itself, but the paper was a euro dimension and didn't fit when folded. My solution was to refold and then cut off the blank margin to get back to the original drawing paper size.

Now both plans fit nicely in the folio and will have a chance of surviving the rough and tumble life of the boat shop (i.e. my basement). I have a separate section dedicated for keeping track of receipts and that leaves four more sections for future builds!

I'm not in a position to get started on the building just yet, but can't wait to start bringing these beautiful plans to life.

Thursday, June 28, 2012

Adirondack chairs - Part 2

Wife: "You know the fourth of July is next Wednesday right?"

Not much time left to get these chairs done! I picked up more wood from the lumber yard and got down to business.

Each seat back is slightly different so the bottom slats are cut based on the seat back width for that chair. From now on I'll have to keep these together, but since one is 1/16" of an inch wider than the other I should be able to tell from the fit. Using the seat slat stock as a guide, I clamped the bottom of the chair together and drilled for the cross braces. The front brace calls for #14 x 3" stainless steel screws which seem awfully big even to me.

Next the back two cross pieces are clamped, glued, and screwed together. These two cross pieces do not meet at 90 degrees and so the edges of the boards need to be adjusted to fit the angle.

Sounds like a great job to break in my new low angle block plane which handled the job beautifully.

All the holes were plugged just like before and then all the assembled pieces were sanded up to 220 grit. I'm using Deks Olje for the finish. It's a Scandinavian marine oil finish that fills the pores of the wood and leaves a semi-gloss finish once the surface of the wood is saturated. Another overkill step, but I want these chairs to last a long time and if it's good enough for wooden boat hulls it should be good enough for a lawn chair!

I hung up the chair bottoms from the dog run cable and brushed on the first coat. The cedar almost changes colors as you look from different angles. All the plugs have the grain oriented perpendicular to the surrounding grain so they really stand out.

Here they are after the second coat working by shop lights. From this angle the main boards appear lighter and the plugs darker.

It will probably take 6 coats or more to fill up the grain and get a nice even finish so I better keep at it.

Not much time left to get these chairs done! I picked up more wood from the lumber yard and got down to business.

Each seat back is slightly different so the bottom slats are cut based on the seat back width for that chair. From now on I'll have to keep these together, but since one is 1/16" of an inch wider than the other I should be able to tell from the fit. Using the seat slat stock as a guide, I clamped the bottom of the chair together and drilled for the cross braces. The front brace calls for #14 x 3" stainless steel screws which seem awfully big even to me.

Next the back two cross pieces are clamped, glued, and screwed together. These two cross pieces do not meet at 90 degrees and so the edges of the boards need to be adjusted to fit the angle.

Sounds like a great job to break in my new low angle block plane which handled the job beautifully.

All the holes were plugged just like before and then all the assembled pieces were sanded up to 220 grit. I'm using Deks Olje for the finish. It's a Scandinavian marine oil finish that fills the pores of the wood and leaves a semi-gloss finish once the surface of the wood is saturated. Another overkill step, but I want these chairs to last a long time and if it's good enough for wooden boat hulls it should be good enough for a lawn chair!

I hung up the chair bottoms from the dog run cable and brushed on the first coat. The cedar almost changes colors as you look from different angles. All the plugs have the grain oriented perpendicular to the surrounding grain so they really stand out.

Here they are after the second coat working by shop lights. From this angle the main boards appear lighter and the plugs darker.

It will probably take 6 coats or more to fill up the grain and get a nice even finish so I better keep at it.

Monday, June 25, 2012

Adirondack chairs - Part 1

I would have called this post "Adirondack chairs - the beginning" but this project started almost three years ago when I got plans and hardware for a pair of folding Adirondack chairs. Sure I could have just bought some chairs but wouldn't it be more fun to make them? And wouldn't they look so much nicer than store bought?

Well this project is off the back burner and will be done by the 4th of July so we can sit in them and watch fireworks. A while back I picked up some clear western red cedar boards and glued the plans onto plywood and cut out the shapes to use as templates.

I cut the WRC boards down roughly to shape back when I bought it but never finished shaping them. So the first step was to sit down with the jig saw for most of the day carefully tracing the patterns and cutting the parts.

Here is the hardware: #10 x 1 1/4", #10 x 2", and #14 stainless steel screws plus the stainless bolts that come with the hardware kit.

The bottom of the seat is made of boards glued up from two parts. The inner part holds the slats and the outer part is larger to cover the end grain of the seat slats

Here you can see how the seat slats will span between the two inner boars with the ends protected by the outer boards.

Next I started on the seat backs. The boards are clamped so that the screw holes can be drilled with a countersink bit. Then the joints are glued up and screwed together with #10 x 2" stainless steel screws.

The counter sink leaves a nice hole for a plug which will clean up the look of these chairs. This is way overkill but that's the fun of making instead of buying.

Plugs come from scraps which I was careful to keep since this cedar isn't cheap and I didn't want to waste any.

The plugs get a bit of glue and then pressed into place. It's the little details like this that I hope will set these apart when they are done and help them last a very long time.

I have run out of things to work on until I buy a couple more western red cedar boards so more to come soon.

Well this project is off the back burner and will be done by the 4th of July so we can sit in them and watch fireworks. A while back I picked up some clear western red cedar boards and glued the plans onto plywood and cut out the shapes to use as templates.

I cut the WRC boards down roughly to shape back when I bought it but never finished shaping them. So the first step was to sit down with the jig saw for most of the day carefully tracing the patterns and cutting the parts.

Here is the hardware: #10 x 1 1/4", #10 x 2", and #14 stainless steel screws plus the stainless bolts that come with the hardware kit.

The bottom of the seat is made of boards glued up from two parts. The inner part holds the slats and the outer part is larger to cover the end grain of the seat slats

Here you can see how the seat slats will span between the two inner boars with the ends protected by the outer boards.

Next I started on the seat backs. The boards are clamped so that the screw holes can be drilled with a countersink bit. Then the joints are glued up and screwed together with #10 x 2" stainless steel screws.

The counter sink leaves a nice hole for a plug which will clean up the look of these chairs. This is way overkill but that's the fun of making instead of buying.

Plugs come from scraps which I was careful to keep since this cedar isn't cheap and I didn't want to waste any.

The plugs get a bit of glue and then pressed into place. It's the little details like this that I hope will set these apart when they are done and help them last a very long time.

I have run out of things to work on until I buy a couple more western red cedar boards so more to come soon.

Tuesday, June 19, 2012

Cutting the decks and floors

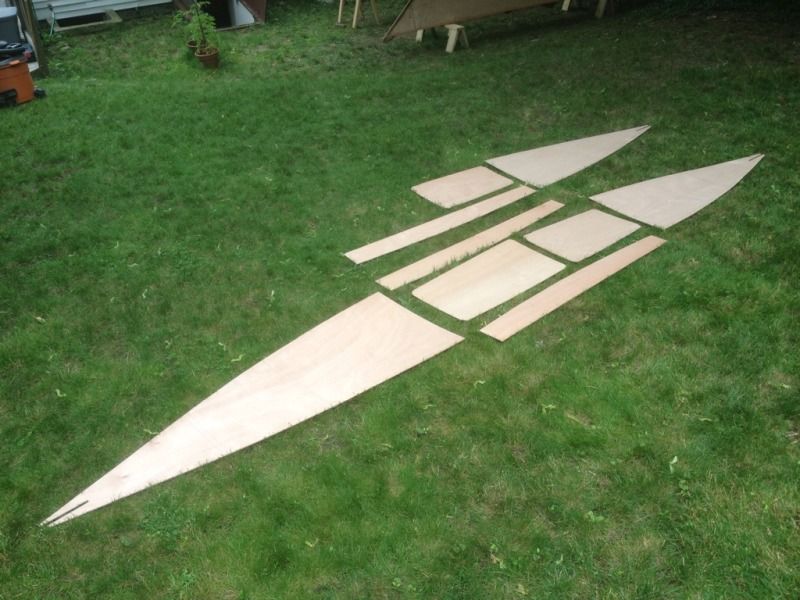

Another free day so we're keeping the momentum going. The hulls were already set up at their proper distance to get a sense of scale so we couldn't help but throw the main beam on to see how it looks. But enough daydreaming, today we are making the floors, fore decks, aft decks and side decks.

Here is our process for making the main decks. We start with a piece about the right size and put a straight edge up against the bulkhead. Clamps hold it tight against the bulkhead and centered across the hull.

The stem location is marked on the underside holding the edge of the pencil point flush with the plywood.

Then cut out the slot and fit it over the stem handle. Next it's pretty straight forward to mark the edges of the hull and trim it down with the jig saw.

Speaking of the jig saw, this is my new Bosch saw which got quite a workout today. I can't believe we made it this far without one and this one is very heavy duty which helps with making nice smooth cuts.

So after all that jig sawing this is what we have to show for it: noth aft decks, both aft floors, three side decks, one front floor and one front deck.

Next up: more epoxy coating, gluing on more fir stringers and back to the lumber store for another sheet of Okoume plywood. Pretty soon we'll be painting the interior and under sides of the decks to get them ready for glue and fiber glassing over the floors.

The first order of business was bringing out the scraps of plywood and seeing what we could get out of each piece to best use the material we had left. We knew after cutting all the bulkheads twice that we wouldn't have enough to finish, but we would like to buy as little extra as possible.

The first pieces cut were the floors. These two floors should be almost the same length according to the plans, but bulkhead 5 which forms the aft face of the aft most floor is about 5" too far forward. Not sure how this happened but we're going with it and will change some of the details on the hatches to make it all look right. The mast will be in the right place and that's what counts so hopefully we don't miss the extra seating space too much. In the end I don't think anyone will notice.

Here is our process for making the main decks. We start with a piece about the right size and put a straight edge up against the bulkhead. Clamps hold it tight against the bulkhead and centered across the hull.

The stem location is marked on the underside holding the edge of the pencil point flush with the plywood.

Then cut out the slot and fit it over the stem handle. Next it's pretty straight forward to mark the edges of the hull and trim it down with the jig saw.

Speaking of the jig saw, this is my new Bosch saw which got quite a workout today. I can't believe we made it this far without one and this one is very heavy duty which helps with making nice smooth cuts.

So after all that jig sawing this is what we have to show for it: noth aft decks, both aft floors, three side decks, one front floor and one front deck.

Next up: more epoxy coating, gluing on more fir stringers and back to the lumber store for another sheet of Okoume plywood. Pretty soon we'll be painting the interior and under sides of the decks to get them ready for glue and fiber glassing over the floors.

Thursday, June 14, 2012

The even bigger gluing day

It's been a long time since we were able to work on the boat and it was time for a big push. The last big push only accomplished about a quarter of what we set out to do. But the days have gotten much longer and today we weren't going to stop until all the fillets were in both hulls and all the keel joints were fiber glassed.

The first hull was already half filleted, so the remaining fillets went pretty quickly. Part of the speed increase was because we moved our epoxy mixing station outside near where we were working to cut down on trips to the basement.

Before we knew it the first hull was fully filleted and ready for fiberglass.

Most of the keel joints were fresh so we were able to press in the fiberglass tape while the epoxy was the consistency of a firm gel. This made smoothing out any bumps or edges easy and let the fiberglass sit nice and smooth against the fillet without any sanding.

Then we brushed on epoxy with a 2" chip brush and worked the tape with a gloved finger like a squeegee. All in all this was much easier than we thought it would be. The only trouble was a bit of unraveling at the ends when we were a bit rough with the tape.

By lunch time the first hull was filleted and taped and curing in the sun.

So we could take a small break, looked out over our work and get psyched up for the next round. The second hull had no epoxy at all, and we had about 6 hours of daylight to finish it.

After lunch the first hull was cured enough to move off the saw horse and finish curing in the sun.

The second hull went just like the first with two exceptions. First, at the filleting stage we filled the stems in three to four passes to prevent excess heat buildup. Second, we worked one 'bay' at a time doing keel, then bulkheads and then glassed the keel. That way as we moved down the boat we left the previous segment complete. Here we have just completed the middle segment and are about to put another layer in the stems.

By the time we brushed epoxy on the last piece of fiberglass the sun was hanging low in the sky but we had reached our goal. We cleaned up our mess and called it a day.

The first hull was already half filleted, so the remaining fillets went pretty quickly. Part of the speed increase was because we moved our epoxy mixing station outside near where we were working to cut down on trips to the basement.

Before we knew it the first hull was fully filleted and ready for fiberglass.

Most of the keel joints were fresh so we were able to press in the fiberglass tape while the epoxy was the consistency of a firm gel. This made smoothing out any bumps or edges easy and let the fiberglass sit nice and smooth against the fillet without any sanding.

Then we brushed on epoxy with a 2" chip brush and worked the tape with a gloved finger like a squeegee. All in all this was much easier than we thought it would be. The only trouble was a bit of unraveling at the ends when we were a bit rough with the tape.

By lunch time the first hull was filleted and taped and curing in the sun.

So we could take a small break, looked out over our work and get psyched up for the next round. The second hull had no epoxy at all, and we had about 6 hours of daylight to finish it.

After lunch the first hull was cured enough to move off the saw horse and finish curing in the sun.

The second hull went just like the first with two exceptions. First, at the filleting stage we filled the stems in three to four passes to prevent excess heat buildup. Second, we worked one 'bay' at a time doing keel, then bulkheads and then glassed the keel. That way as we moved down the boat we left the previous segment complete. Here we have just completed the middle segment and are about to put another layer in the stems.

By the time we brushed epoxy on the last piece of fiberglass the sun was hanging low in the sky but we had reached our goal. We cleaned up our mess and called it a day.

Subscribe to:

Comments (Atom)

.JPG)

.JPG)