Lowes and Home Depot happen to sell 48" long 6" wide 1/4" thick strips of various species that were perfect for planking stock and didn't require any planing or prep work. None of the options were particularly suited to boat building, but then this is just a toy. Poplar was inexpensive, had light clear grain and was the easiest to bend, so that's what I went with. Most of the boards have off color sapwood so it took picking through almost every store in the metro Boston area to find 6 clear boards with matching color.

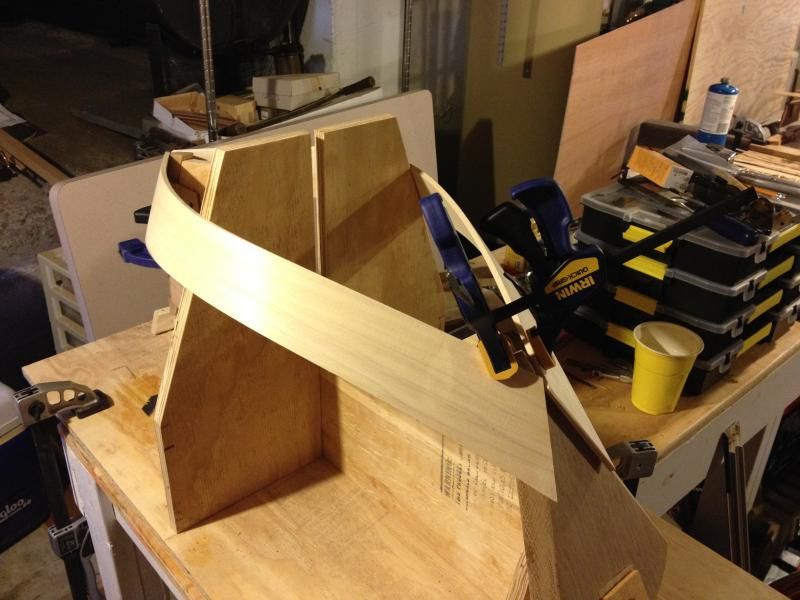

There is a lot of stress on the plank ends so I started by gluing the first plank to the stem and letting it set up before attempting the bending.

For steaming I borrowed (with permission) the wife's steam mop. It looks pretty odd but it actually worked really well for these small thin planks and didn't require building a steam box just for this little project.

After the steaming the planks bent pretty easily and lined up with the transom bevels better than expected.

Finally the planks are attached to the transom with glue and countersunk stainless screws.

Two planks down, four more to go...

No comments:

Post a Comment